"All The Services You Need"

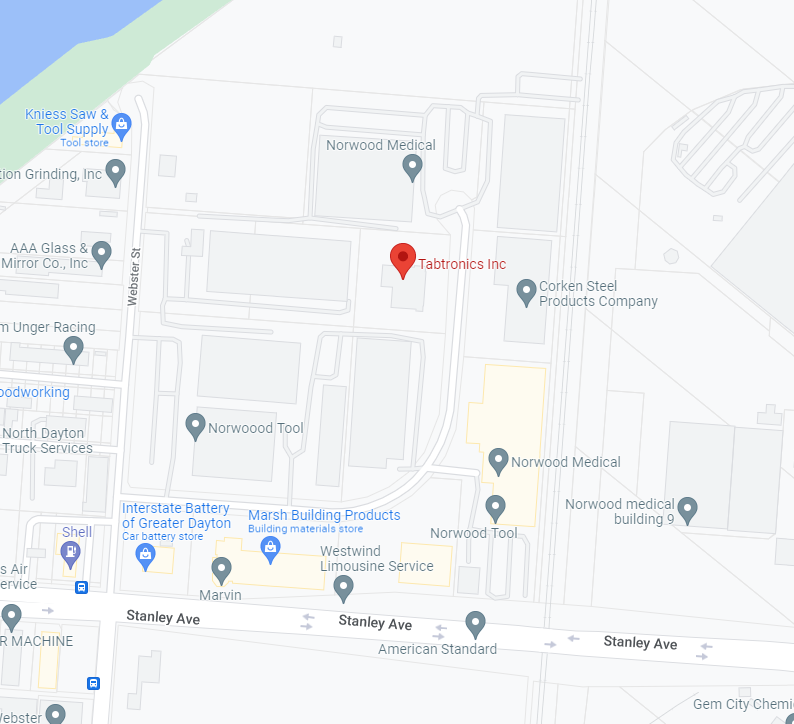

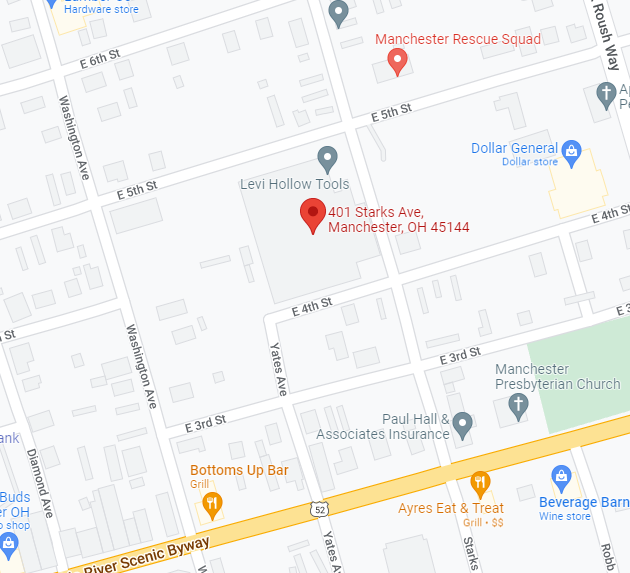

Mirac Tabtronics provides world-class electronics manufacturing and development services that consistently exceeds our customer’s expectations. We achieve this through a focus on competitive pricing, on-time delivery, team building and continual improvement of our quality management system. As a contract manufacturer, we have the flexibility to modify our facilities, equipment, and personnel to suit your production requirements. Our locations are meticulously operated and maintained. Below are some of the equipment capabilities and services we offer.

Surface Mount Technology

Mirac Tabtronics has four high-speed surface mount lines equipped with solder paste inspection and re-flow ovens. From prototype builds to large volume production runs, we have the capacity to meet your needs.

Axial Insertion

With two Universal Axial Insertion machines, Mirac Tabtronics has the capacity to meet all your company's leaded through-hole component technology needs.

Automated Optical Inspection

Mirac Tabtronics uses Automated Optical Inspection machines to inspect 100% of our SMT production builds. Our staff has over 25 years of experience in high-speed AOI and SMT rework.

X-ray

With the use of the VJ Electronix & Vertex II X-ray machines, Mirac Tabtronics has the ability to detect opens, shorts, voids, and other BGA, CSP, and flip chip faults.

Selective Solder

Mirac Tabtronics can handle basic to complex through-hole selective soldering processes in leaded or lead-free solder. Selective soldering provides an automated solution to hand soldering; when wave soldering is not an option. This is a cost effective solution when parts are populated on both sides of the board.

Wave Solder

With our Seho Powerwave and Electrovert Vectra soldering systems, Mirac Tabtronics is able to offer leaded or lead-free soldering. Whether your PCB build is conventional or complex, we will deliver a cost effective, high quality wave soldered assembly each and every time.

PCB Water Wash

Mirac Tabtronics ensures that all flux and contaminants are removed from your PCB with the use of deionized water. The Nu/Clean Galaxy PLUS aqueous cleaner system takes your circuit boards to a higher level of cleanliness.

Conformal Coating

When electronics must withstand harsh environments, Mirac Tabtronics offers PCB conformal coating to act as a protection against moisture, dust, chemicals, and temperature extremes that, if uncoated, could result in damage or failure.

Encapsulation

When electronics must withstand extreme conditions, Mirac Tabtronics offers PCB encapsulation (potting) to protect parts from harsh environments, abrasion, to add another level of protection.

ICT (In Circuit Test)

The CHECKSUM 12KN Test System is ideal for in-circuit test. The dual-level operation allows for in circuit testing as well as functional testing using the same fixture, at the same time.

Functional Testing

Mirac Tabtronics provides functional testing per customer specifications, for both PCB and wire needs. Functional testing ensures a high quality product is being produced and reduces the risk of failures and costly expenses.

Wire Processing

With over 15 presses and 5 cut and strip wire machines, Mirac Tabtronics has the capability to address your wire needs. From small volume to large volume, our trained professionals will ensure a high quality product.

Wire Crimp Center

For high volume wire assembly needs, the Schleuniger Crimp Center 36 S

is a fully automatic crimping machine with up to six processing stations. Dynamic, powerful servo drives, combined with an intelligent control system, provide high production rates to meet the most demanding production schedules.

Wire Wrap Labeling

Mirac Tabtronics utilizes the Brady Wraptor A6500 to print and apply labels in less than 5 seconds. With the capability to wrap up to 7000 labels a day, no job is too big or too small, when it comes to improving efficiencies in the field.

Turnkey Solutions

Mirac Tabtronics specializes in turnkey solutions. Let us work along side you from the early concept stages to floor plan cell optimization to bring your product to market.